Look at this project for lean construction! Assembly type, BIM Modeling, Aluminum Template, Plastering-Free System

Author:www.precast.com

Time:31/07/2020

The swan lakeside garden project in Longgang District, Shenzhen has emerged in the gleaming lake. With the courage of the project team, the ten high-rise buildings have raised their “swan necks” after being fully capped. The project is located on the front line of the Yantian Reservoir and will be fully delivered to use by the end of this year. The "elegant" swan lakeside garden project has an unusual "exquisiteness" and is more "hard-core" technology blessing.

As a demonstration project of lean construction in local government, the Shenzhen Swan Lakeside Garden project is based on the characteristics of the project, implements the general contracting management concept, takes lean construction as the starting point, and firmly grasps the interspersion of efficient processes.

Since the resumption of work on February 25, the project's high-point and advanced positions have taken planning control as the core element of efficient performance, and established a coordinated "design, recruitment, construction, and acceptance" plan management system to grasp the front-end "blueprint mobilization" Guided by “planning”, “main line of construction” at the top and middle end, and “main line of acceptance” at the back end, sort out the main construction process flow, design process interleaving models, and implement reasonable interleaving processes to reduce idleness of working face, control key construction period nodes, and grasp With a balanced and compact construction pace, the official elevators of the 10 main buildings were installed one month before the main building was topped, and the first main building was topped five days in advance. The monthly output value of the project exceeded 100 million yuan in April.

The "growth technique" and automatically "ascending"

We have a set of cost reduction and efficiency combination punches! As long as you move your fingers, you can achieve safe ‘climbing stairs’! "Talking about the "growth technique" of the floor, the project manager Du Peng excitedly pointed to the all-steel climbing frame running on the roof.

"Compared with traditional manual scaffolding, the all-steel climbing frame has a significant cost-reduction and efficiency-increasing effect. Using an electric hoist, you can climb a floor within 2 hours by pressing the control button." Du Peng introduced, the Swan Lakeside project has a total of 10 The 462-storey building is constructed with all-steel climbing frames for each building, and there are processes interspersed with blessings, which can save 60 days of construction period for the project.

The all-steel climbing frame is made of steel, which has the advantages of fire and flame retardant, which completely eliminates the hidden danger of fire in the high-altitude frame. And the design of each accessory fully takes into account the safety of on-site construction and the needs of humanized operation, the frame body is easy and quick to assemble, and the modular lifting and dismantling save labor and effort.

In addition, the all-steel climbing frame also uses an intelligent control system to monitor the force of each machine position in real time, and automatically shut down and alarm when overloaded or under-loaded, so as to minimize the project construction risk.

However, the implementation process of the all-steel frame is not a "smooth path".

The facade of the main building of the Swan Lake Garden Project is complex, which poses many challenges to the deepening design of the all-steel climbing frame. In order to improve the construction efficiency, the project team worked hard and brainstormed to find the best solution, and finally decided to add walkway slabs to the special-shaped part of the floor, the bottom was reinforced with movable keels, and the upper hinge was connected with the climbing frame pole. In this way, both It meets the design requirements and satisfies the use function of the all-steel climbing frame.

"Black technology" superimposed, keep improving

Du Peng's "combination boxing" for reducing costs and increasing efficiency includes, in addition to all-steel climbing frames, aluminum mold systems, plaster-free systems, prefabricated buildings, and BIM modeling. The details can be seen in the ingenuity of the builders.

The best match "mate" for steel climbing frame

The best matching "partner" for the all-steel climbing frame is the aluminum mold system.

The overall design of the all-steel climbing frame is beautiful and the protective effect is good. When matched with the aluminum mold system, it can realize the simultaneous construction of the main structure with the exterior wall bottom coating finish, aluminum alloy exterior windows and railings.

The formwork project of the project follows the principle of installing the shear wall column first and then installing the beam slab surface, and adopts the whole one-time pouring. The use of aluminum formwork improves the quality of concrete forming, thereby achieving a "plaster-free" effect. "The plaster-free system will further reduce the cost and increase the efficiency of the project!" Wu Leixin, the project commercial manager, repeatedly praised the aluminum mold + all-steel climbing frame + plaster-free system.

In addition, the project will set up cantilevered protective sheds in each building section, install hanging baskets in advance, insert the exterior wall shutters in sections, paint construction, accurately intersperse, and construct synchronously.

"Building blocks" to build a house

Building No. 4 of the project is a prefabricated affordable housing, which uses prefabricated bay windows, prefabricated balconies, prefabricated stairs, prefabricated balconies exterior walls and lightweight partition walls with a total of 1,419 prefabricated components, which are highly energy-efficient and environmentally friendly. In addition, prefabricated road panels are used for the construction of the temporary main road in the 06 block of the project, and most of the outdoor garden drainage ditch is optimized to the finished resin prefabricated drainage ditch, which reduces the quality risk and improves the first-time success rate.

BIM empowerment

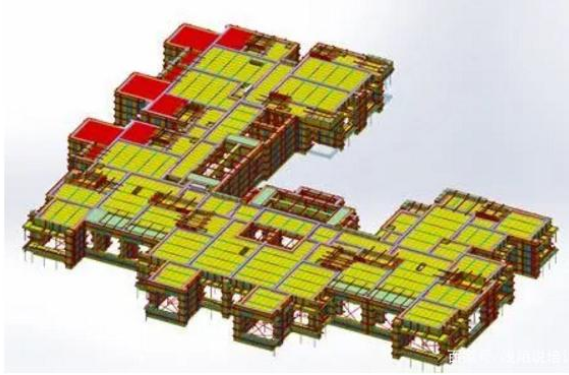

The project involves many professions and the construction content is complex. The project team created BIM models of various professions, checked the errors and omissions in the construction drawing design stage, solved the collisions and conflicts between professions, visually inspected the models through the real-person ratio roaming function, and performed net height analysis , Spatial analysis, etc.

"In the aluminum template layout design, we use the BIM model to deepen the review of complex nodes to reduce errors, omissions, rework and template waste." Project technician Zeng Lu introduced the main functional equipment rooms, garages and public areas in the basement of the project. All adopt BIM modeling, integrate architecture, structure, and electromechanical, carry out collision inspection and ceiling height control optimization, reduce the rework of pre-embedded mechanical and electrical installation and missed rework, reduce quality risk, and improve construction efficiency and quality.

Well type special construction hoist

Adopt innovative use of hoistway-type special construction elevators to reduce the one-time edge protection investment of gear-type external elevators, the impact of facade operations and the subsequent impact of closing and closing, improve safety management level, and improve construction efficiency.

苏公网安备 32041102000002号

苏公网安备 32041102000002号