The first 3D printed habitable building in China was delivered, completed in 50 hours!

Author:www.scg.com.cn

Time:13/09/2022

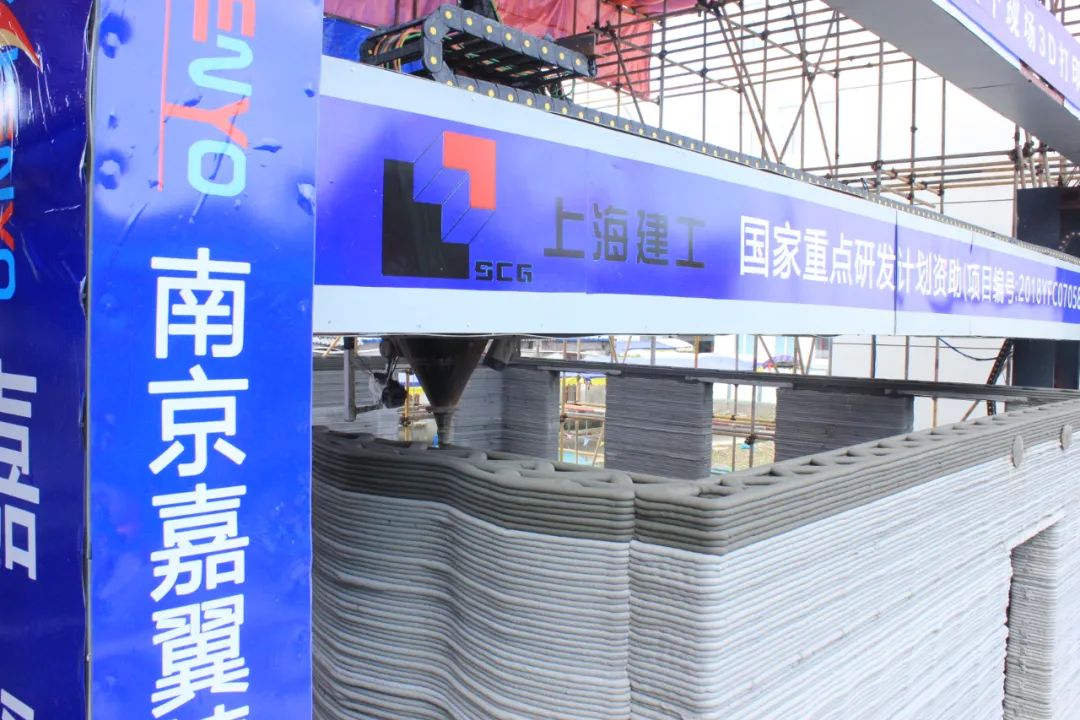

Introduction: In recent days, at the Lingyan Community Health Service Center in Liuhe District, Nanjing, a two-story building under construction is stacked and taller than a flower cake, and it is beginning to take shape. It looks unremarkable on the outside, but there are high-tech behind it.

It is the first truly habitable and deliverable two-storey building in China that is 3D printed on site, with a height of 6 meters and a usable area of 52.8 square meters, led by the Shanghai Construction Engineering Group, it will be used as an exhibition hall for the history of the academy after completion. Chen Xiaoming, chief engineer of Shanghai Construction Engineering Group, said: "On the road of intelligent construction exploration, large-scale 3D printing construction is the technical direction of Shanghai Construction Engineering's priority development."

Two-story building renderings

Truly liveable and deliverable

This 3D printing building, also known as the Shanghai Construction Engineering 3D Printing Technology Experimental Building Project, is one of the demonstration projects in the national key R&D project led by Shanghai Construction Engineering Group. Shanghai Construction Engineering, Southeast University and Nanjing Jiayi Precision Machinery Manufacturing Co., Ltd. jointly formed a project team.

The two-story building printed in situ will eventually be put into use as the academy history exhibition hall of Lingyan Community Health Service Center in Liuhe District, Nanjing.

The entire building took about 50 hours to print. The 3D printing equipment independently developed and manufactured by the project team, the self-developed 3D printing concrete material, and the firstly designed building structure have all laid an important foundation for the smooth implementation of on-site printing.

The equipment currently on site is the first in-situ 3D printer in China to realize the pumping of coarse aggregate concrete materials. The printing range is 24 meters long, 8.5 meters wide and 6 meters high. The nozzle diameter of the print head is 40 mm and 50 mm, which can realize the intelligent on-site in-situ 3D printing construction of super-large structures.

The printing equipment is in place, and the "efficient cooperation" of printing materials is even more needed. The 3D printing concrete material developed by the project team was used on site, and in the on-site in-situ 3D printing, 3D printing concrete material containing coarse aggregate was used locally for the first time: the ready-mixed concrete containing coarse aggregate is transported to the printing chamber by pumping technology, and after secondary stirring in the printing chamber, it is extruded through the printing head and printed.

The use of coarse aggregate can not only reduce the cost of materials, but also solve the problem of easy cracking of the currently used 3D printing mortar. The project team also developed solid waste materials that can be used for 3D printing, which is in line with the current development concepts of solid waste recycling, energy saving, emission reduction and environmental protection.

At present, the biggest challenge in the promotion and application of 3D printing buildings is the lack of corresponding perfect standards. For this reason, the project team first designed a "frame + masonry + laminated board structure" 3D printing building that meets the current standards. The self-supporting wall and partial column and beam formwork are completed by 3D printing technology. The frame structure is used as a load-bearing structure. The successful design of this 3D printed building structure has created important conditions for the delivery and use of the project.

苏公网安备 32041102000002号

苏公网安备 32041102000002号