Build smart! Beijing's first high-rise modular box building was successfully hoisted for the first time

Author:www.baijiahao.baidu.com

Time:08/04/2022

On March 30, the first modular box-type house in Beijing's key project and Beijing Yizhuang blue-collar apartment project was hoisted into place, marking the project's entry into a comprehensive and rapid construction stage. It is reported that the project is currently the tallest and largest modular building in the country.

It is reported that the Beijing Yizhuang blue-collar apartment project, featuring modular green and intelligent construction, is 32 meters high and has 9 floors, with a construction area of 120,000 square meters and an overall assembly rate of 92%. This is a Beijing AAA-level modular demonstration project with ultra-high assembly rate. After completion, it will provide 1,810 houses for industrial skilled workers. Among them, 1500 are modular box houses.

"Relying on the world's first prefabricated building intelligent construction platform and the BM board connection technology connecting the boxes, 10 workers on site cooperate with one tower crane to complete the hoisting of one box-type house every hour. 4 tower cranes operate at the same time, 44 box-type houses can be hoisted in one day, and the hoisting accuracy can be controlled within 5 mm." Introduced by Jiang Jie, project manager of CSCEC Yizhuang Blue Collar Apartment.

Jiang Jie introduced that after the first modular box-type house was successfully hoisted into place, it is expected that more than 1,500 sets of modular box-type houses can be hoisted in 45 days. By April 30, the hoisting tasks of the project's modular house-type houses can be completed. The entire project is expected to be fully completed and put into use on June 30, 2 months ahead of the original planned completion date on August 30.

It is understood that the assembly and construction process of the modular box-type house used in the Beijing Yizhuang blue-collar apartment project is similar to "building blocks", which is environmentally friendly and economical. The zero-humidity operation during construction can save 70% of water and achieve zero sewage discharge. "Building blocks" are lapped on site, eliminating the need to build scaffolding and formwork, which can reduce construction waste by 80%; eliminating welding and other processes, saving 70% of electricity; the utilization rate of recyclable materials reaches 90%, achieving zero material loss. At the same time, its detachable, replaceable and recyclable component attributes greatly reduce the maintenance cost after occupancy.

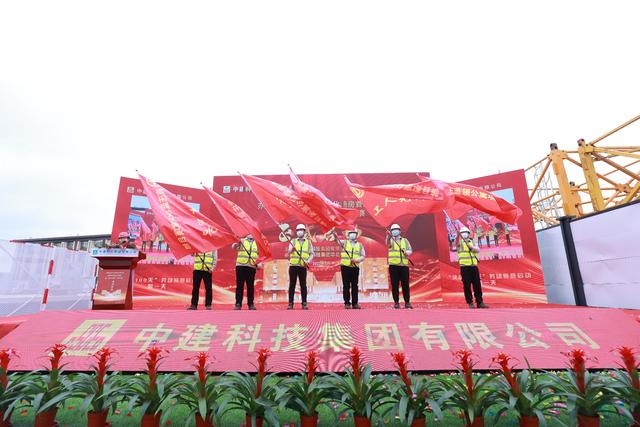

In addition, with the hoisting of the first modular box-type house in place, the "100 Days of Decisive Battle" labor competition of CSCEC officially kicked off. The labor competition takes the form of a "four competition" competition of speed, innovation, quality and safety. Party members, youth and workers of the project team strive to create "Party Member Pioneer", "Youth Civilization" and "Worker Pioneer", and strive to achieve the project's full completion ahead of schedule.

苏公网安备 32041102000002号

苏公网安备 32041102000002号