From 450 days to 72 days, let’s look at Haikou prefabricated + near-zero carbon emission buildings!

Author:www.baijiahao.baidu.com

Time:09/09/2021

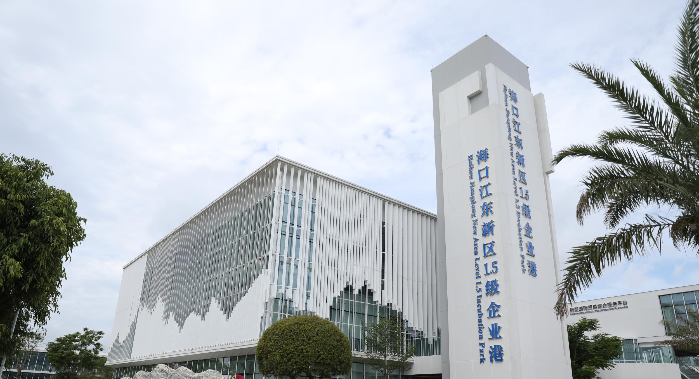

450 days and 72 days, this is the construction period required for traditional concrete buildings and prefabricated buildings. In the 23,000-square-meter construction project of the 1.5-level enterprise port project in Haikou Jiangdong New Area, the large-scale use of prefabricated buildings made it take only 72 days to complete the construction that originally took 15 months at the earliest.

The 1.5-level enterprise port project in Haikou Jiangdong New Area adopts the "steel structure + modular" prefabricated building form to be completed in just 72 days.

It is understood that the 1.5-level corporate port in Haikou Jiangdong New Area is also Hainan's first practical construction project with nearly zero carbon emissions. Let us walk into the prefabricated building together and reveal the "magic" of "building blocks" to build a house.

Fast forward time "6 times speed"

Save one third of consumables

Comparison of photovoltaic glass (darker) and ordinary glass.

In 72 days, how did the construction of 23,000 square meters (close to the size of 3 standard football fields) start to completion? The reporter saw at the 1.5-level corporate port in Jiangdong New District, Haikou that the buildings in the park are no different from ordinary buildings in appearance. "More than 70% of the building components of the entire project are prefabricated in the factory." Feng Jian, Secretary of the Party Committee and General Manager of the Hainan Branch of China State Construction Engineering Group Co., Ltd., introduced that the "time magic" of prefabricated buildings lies in the parallelism of on-site engineering and factory prefabrication.

It is understood that the construction of the 1.5-level enterprise port in the Jiangdong New District of Haikou started on January 20 this year. While leveling the land and foundation construction, the factory in Huizhou also simultaneously started the production of building modules according to design requirements.

"Prefabricated buildings are like'building blocks'. We prefabricated floor slabs, wall panels and other components in the factory, then transport them to the construction site, and then assemble them together, thus greatly reducing the carbon emissions during the construction process." Feng Jian said that the project adopts a "steel structure + modular" prefabricated building form. The largest module is 17 meters long and weighs about 25 tons. The smallest module is about 10 meters long and weighs about 7 tons. It integrates structure, pipelines, and decorations to give full play to the advantages of prefabricated buildings.

The 1.5-level enterprise port project in Haikou Jiangdong New Area adopts the "steel structure + modular" prefabricated building form to be completed in just 72 days.

"If traditional concrete construction is used, it will take at least 15 months and about 450 days." Feng Jian introduced that the 23,000-square-meter building of the project was constructed with 297 modular boxes and 800 tons of steel structural components. In 20 days, the main steel structure of 3 7966 square meters was capped, and 297 modular units were hoisted in 8 days. The curtain wall, electrical and mechanical and decoration construction of 7 buildings of 23,000 square meters were completed in 30 days, and all the projects were completed in 72 days, which is 6 times faster than traditional construction.

In addition, prefabricated buildings also make full use of the advantages of steel structures. "Because steel structure has the characteristics of light weight and high strength, compared with concrete structure, the total weight of steel structure building is about one-third of that of reinforced concrete building, which greatly saves the consumption of resources." Feng Jian said that the project uses the superior seismic performance of the steel structure to greatly reduce the investment in seismic measures and achieve carbon reduction and emission reduction. At the same time, all modules of the project can be moved, split and reorganized, and recycled.

Glass sandwiched photovoltaic panels

Both heat insulation and power generation

Photovoltaic glass

As Hainan's first practical building project with nearly zero carbon emissions, low carbon is also reflected in the overall design of the park. "In addition to the unique advantages in building materials, the project also applies intelligent systems such as smart light poles, smart charging piles, photovoltaic glass, and intelligent decomposition of kitchen waste." According to Zhang Bo, head of the Strategic Development Department of Haikou Jiangdong New Area Development and Construction Co., Ltd., the project further makes overall considerations and deployments in terms of improving clean energy production and reducing energy consumption in the park, and using smart construction to reduce carbon emissions.

The reporter saw at the party-mass activity service center of the project that the roof of the building is equipped with roof photovoltaic solar panels, and part of the glass curtain wall is joined with cadmium telluride film double glass laminated hollow glass photovoltaic components to realize the function of power generation. Compared with ordinary glass, the color of photovoltaic glass is darker. If you observe closely, you can see the dense photovoltaic panels "hidden" in the middle of the glass.

"The panels in the photovoltaic glass absorb heat through the photovoltaic panels and connect them to the building's computer room through leads to achieve power generation." According to Zhang Bo, in addition to providing electricity for buildings, photovoltaic glass also has the functions of maintenance, heat insulation, and beauty of ordinary glass curtain walls, realizing the green building concept from passive energy saving to active power generation. At present, the building's photovoltaic power generation can meet the needs of daily office activities.

In 2020, the prefabricated building area in Hainan will exceed 10 million square meters

It is understood that since 2018, the prefabricated building area in Hainan Province has been increasing year by year. By the end of 2020, the total building area of prefabricated projects under construction and through the implementation plan review will reach 16.36 million square meters. In 2020, the prefabricated building area in Hainan will reach 11 million square meters. Currently, Hainan has established 14 industrial bases, and 7 industrial bases under construction or planned. At present, the annual production capacity of precast concrete structural parts is about 740,000 cubic meters, and the annual production capacity of steel structural parts is about 310,000 tons. According to the "Fourteenth Five-Year Plan (2021-2025) for Green Buildings (Prefabricated Buildings) in Hainan Province" issued by Hainan, it is planned that by the end of 2025, Hainan prefabricated buildings will account for more than 80% of new buildings. Two national-level prefabricated building demonstration cities have been built, and the annual production capacity of prefabricated components can be balanced between supply and demand.

"The promotion and application of prefabricated buildings has become an important part of improving the quality of the ecological environment." The relevant person in charge of the Hainan Provincial Department of Ecology and Environment stated that as one of the landmark projects in the construction of the national ecological civilization experimental zone in Hainan Province, the prefabricated building has been written into the Hainan Provincial Government Work Report. It has the advantages of high industrialization, short construction period, convenient transportation of components, energy saving and environmental protection. The development of prefabricated buildings not only meets the development requirements of Hainan Province to build a national ecological civilization experimental zone, but also contributes to the development of Hainan's "carbon peak" and "carbon neutral" work.

苏公网安备 32041102000002号

苏公网安备 32041102000002号